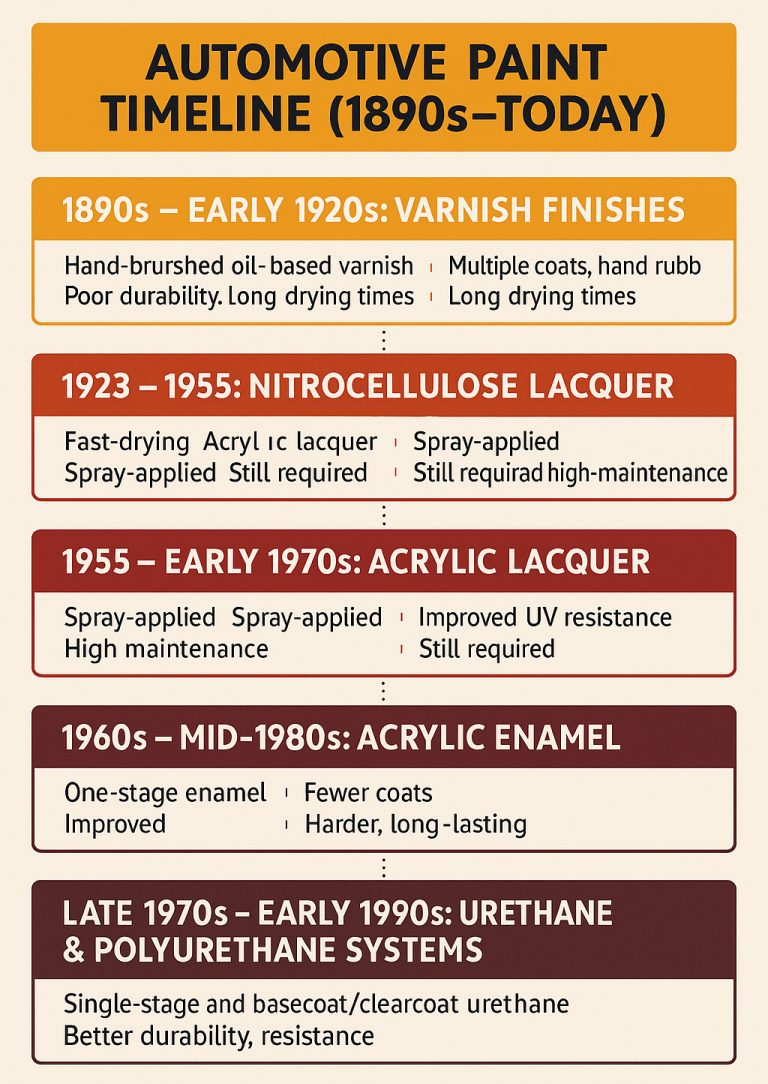

🚘 Automotive Paint Timeline (1890s–Today)

🪵 1890s – Early 1920s: Varnish Finishes

Type: Hand-brushed oil-based varnish (copal, linseed oil, shellac)

Application: Multiple coats (10–20), hand-rubbed

Dry Time: Days to weeks

Durability: Poor (UV damage, cracking)

Used on: Wood-bodied vehicles and early steel panels

Downfall: Too slow and labor-intensive for mass production

💥 1923 – 1955: Nitrocellulose Lacquer

Introduced by: DuPont in 1923 (“Duco”)

Type: Fast-drying lacquer derived from gun cotton chemistry

Application: Spray-gun applied, multiple thin coats, hand-buffed

Dry Time: Minutes to hours

Durability: Glossy but prone to fading, cracking, and yellowing

Used by: All major U.S. manufacturers

Bonus: Easy to repair, blend, and polish

Downfall: Required frequent upkeep and had low chemical resistance

🎨 1955 – Early 1970s: Acrylic Lacquer

Introduced by: GM in 1955 (DuPont “Lucite”)

Type: Chemically improved lacquer with better UV resistance

Application: Same as nitrocellulose, but higher gloss and less fading

Used by: GM (Cadillac, Olds), then others followed

Durability: Slightly better than nitrocellulose but still required upkeep

Downfall: Environmental regulations and better alternatives on the rise

🧴 1960s – Mid-1980s: Acrylic Enamel

Type: One-stage enamel (color and gloss in one layer)

Curing: Air-dry or bake (thermoset version used in factories)

Application: Fewer coats, faster production, high-gloss finish

Used by: Ford, Chrysler, GM — industry standard in this era

Durability: Harder and longer-lasting than lacquer

Downfall: Difficult to repair and blend; environmental concerns

🛡️ Late 1970s – Early 1990s: Urethane Enamel & Polyurethane Systems

Type: Single-stage urethane or basecoat/clearcoat urethane

Introduced: Late 1970s (PPG, DuPont, BASF innovations)

Application: More durable, chemical-resistant, and glossy

Basecoat/Clearcoat (BC/CC): Two-step system became standard

Basecoat: Color

Clearcoat: Gloss and protection

Used by: All major automakers by mid-1980s

Durability: Excellent — resists UV, scratches, and chemicals

Downfall: More expensive and complex for DIY use

🌍 1990s – Present: Modern Urethanes, Waterborne Systems, and Low-VOC

Basecoat/Clearcoat urethane: Industry standard today

Waterborne basecoats: Introduced due to EPA VOC regulations

Common systems:

2K urethane (catalyzed, two-component)

Waterborne base + 2K urethane clear

Durability: Outstanding, can last decades

Used by: All OEMs worldwide

Shifts:

Low-VOC formulas to meet environmental laws

Ceramic clears and self-healing topcoats in luxury cars